- 한국어|

- HOME|

- ADMIN|

- CONTACT US

HOME > Polpack > Features of Polpack’s Film

By using reliable Dry Lamination film and light-weight short distribution Co-extrusion film,

Indisair's Polpack can give you a variety of choices.

| Section | Film Constructions | Thickness | Applications |

|---|---|---|---|

| Premium | Dry Lamination Film + Dry Lamination Film | 80㎛ , 100㎛ , 120㎛ | Long-term domestic / overseas distribution, expensive products |

| Standard | Dry Lamination Film + Co-extrusion Film | 70㎛ | Short-term domestic / overseas distribution, industrial product |

| Entry | Dry Lamination Film + Co-extrusion Film | 45㎛ , 60㎛ | Domestic short-term distribution, low-cost product |

※ It is divided into three types of film constructions by its price (High, medium and low), and again divided by its thickness to optimize the design and competitiveness.

INDIS Air selects materials and designs, with the consideration of the feature of the products packaged, ,

expiration date, logistics method and price conditions.

| Product | A House-Hold Big Size Monitor |

|---|---|

| Price | $1,000 range |

| Distribution Period | 1~6 months |

| Delivery Method | Freight, Parcel, Door-to-door(Domestic) |

| Introduction | It takes 20 to 30 minutes to pack the item with existing bubble wrap, causing lots of stress.It doesn't look good and it is hard to throw it away because of its size. Up to 18% of damage during cargo delivery. |

| Design Application | Using its own internal package and applying the outside only.To reduce damage during delivery, use Dry Lamination Film 80㎛ + Dry Lamination Film 80㎛.Apply with air pillars height 30mm.Designed not to be peel off even if 4~6 air pillars are blown out.Reduce the packing time. |

| Effects | Significant reduction in defect rate during delivery (approximately 1/100th level)The courier only allows delivery of large products when using the Polpack.Reduce packing time to less than 5 minutes. Saving the labor costs (Reducing 4 workers to 2) Reducing 10% packaging material and improving work environment. |

| Product | Side View Mirrors |

|---|---|

| Price | $300 |

| Distribution Period | 1~3 months |

| Delivery Method | Parcel, Door-to-door(Domestic / Overseas) |

| Introduction | Long packing time and damage frequently occurred during delivery with normal bubble wrapConsumers were unsatisfied with bubble wrap packaging. |

| Design Application | Useing Dry Lamination Film 70㎛ + Co-extrusion Film 70㎛ for internal packaging.Apply with air pillars height 15mm.Pocket type design to increase the product value and protecting all 6 edges.Increased loading capacity by enabling the packages to stand upright. |

| Effects | Reducing packing time from 180sec. to 10 secReducing labor costs from 4-7 to 2 workers.Minimizing product damage during delivery.Increasing 20% loading capacity by improving packing method.Better working environment. |

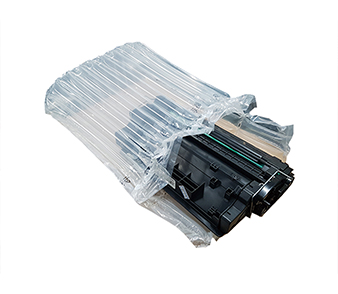

| Product | Inkjet Toner |

|---|---|

| Price | $30 ~ $80 |

| Distribution period | in 1 month |

| Delivery method | Parcel (domestic) |

| Introduction | Long packing time and damage during delivery with existing bubble wrapDamaged product also affects to the other products due to the leakage issue. |

| Design application | Apply to Dry Lamination Film 60㎛ + Co-extrusion Film 60㎛ for internal packagingApply with air pillars height 15mm.Designed as a pouch type to increase the product value and protect all 6 edges together. |

| Effects | Reduce packing time to 10 secs (3 minutes when using bubble wrap)Reducing labor costs from 4-5 to 2 workersMinimize the product damage during delivery10% reduction in cost competitiveness.Improved the working environment. |

| Product | Wine Gift Box |

|---|---|

| Price | $50 ~ $300 |

| Distribution period | Same day |

| Delivery method | Parcel (domestic) |

| Introduction | Long packing time and damage during delivery with existing bubble wrap.Damaged product also affects to the other products due to the leakage issue. |

| Design application | Dry Lamination Film 60㎛ + Co-extrusion Film 60㎛ for internal packaging.Apply with air pillars height 25mm.Designed as a pouch type to increase the product value and protect all 6 edges together. |

| Effects | Reduces packing time under 10 secs (5 minutes when using bubble wrap)Reducing labor costs from 4 to 2 workers.Application of printing Fragile mark minimized the product damage during delivery.20% reduction in cost competitiveness.Improved the working environment. |